Precision machining has many advantages. We have previously shared with you the specific advantages of precision machining, the most obvious of which is the ability to achieve high precision that ordinary machining cannot achieve. High precision also relies on precision machining equipment and accurate restraint systems, and uses precision masks as intermediaries to achieve extremely fine control over the amount of external surface material removed or added. So, what are the specific characteristics of precision machining? Below, our chief engineer from Yujiaxin Technology will give you a detailed introduction:

1、 Precision machining of parts

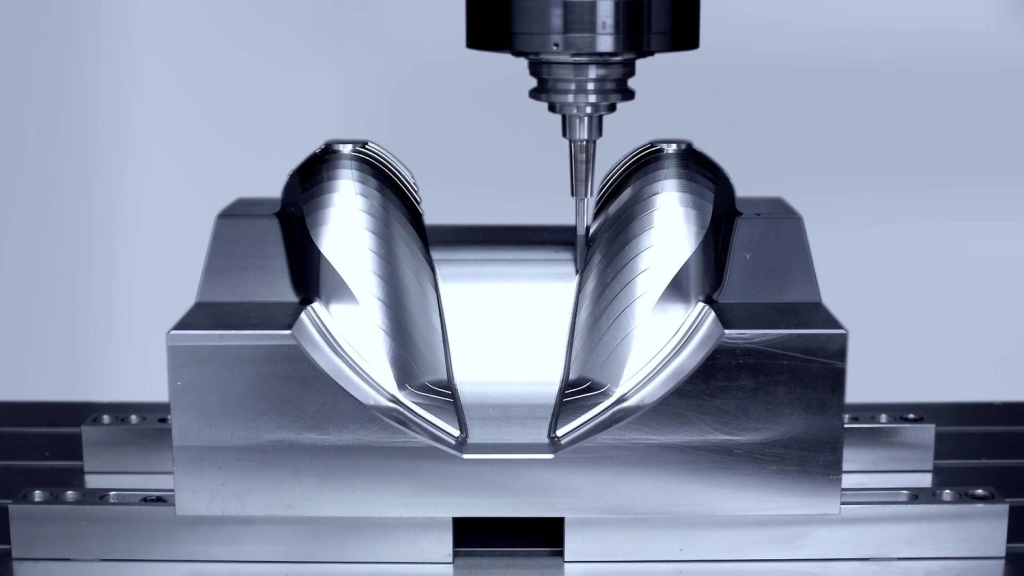

There are mainly precision turning, mirror grinding, and grinding. Micro turning is performed on precision lathes using finely ground single crystal diamond turning tools, with a cutting thickness of only about 1 micron. It is commonly used to machine high-precision and highly polished parts such as spherical, non spherical, and flat reflectors of non-ferrous metal materials. For example, the non spherical reflector with a diameter of 800 millimeters used in processing nuclear fusion devices can achieve a maximum accuracy of 0.1 micrometers and an external roughness of Rz0.05 micrometers.

2、 Precision parts processing

When the precision machining accuracy of precision parts is aimed at nanometers, or even atomic units (atomic lattice distance of 0.1-0.2 nanometers), ultra precision part cutting methods are no longer suitable. It is necessary to use special precision part machining methods, such as chemical energy, electrochemical energy, thermal energy, or electrical energy, to make these energies exceed the joint energy between atoms, thereby removing the adhesion, joint or lattice deformation between some atoms on the surface of the workpiece, in order to achieve the goal of ultra precision machining. This type of processing includes mechanochemical polishing, ion sputtering and ion implantation, electron beam exposure, laser beam processing, metal evaporation, and molecular beam epitaxy.

That’s all for today’s introduction to the characteristics of precision parts processing. If you want to learn more information, you can visit our enterprise news and information center. Shenzhen Yujiaxin Tech CO.,LTD. is a professional manufacturer of metal non-standard parts, with years of technical accumulation in the manufacturing of precision parts such as stainless steel, titanium, aluminum, etc. with a diameter of 0.5-20mm.

Our main products include: non-standard micro components, stainless steel components, medical equipment accessories, lighting accessories, fasteners, connectors, instrument accessories, axis shaft sleeves, fiber optic connectors, LC tail handles, SC tail handles, precision mechanical parts, fiber optic communication accessories, screws and nuts, electronic product accessories, copper, aluminum rivets and more than 200 varieties of high standard, high-quality and high cleanliness products for civilian and military use, for customers to choose from. In addition, we can also manufacture products that satisfy customers according to their different requirements.