Precision hardware processing is a process that converts various raw materials, including stainless steel, copper, aluminum, iron, etc., into various high-precision and high-density hardware parts through lathes, milling machines, drilling machines, polishing and other precision mechanical equipment according to customer drawings or physical samples. These parts are widely used in various fields, such as screws, motor shafts, model car parts, fishing gear accessories, and dog bone precision hardware, etc. They play a vital role in production, assembly, fixing and decoration.

The process of precision hardware processing is a delicate and complex process chain. First, according to production needs, the raw materials are cut. This step is crucial, which determines the smooth progress of subsequent processing and the accuracy and quality of the final product. After the cutting is completed, different processing methods will be adopted for parts of different sizes and shapes.

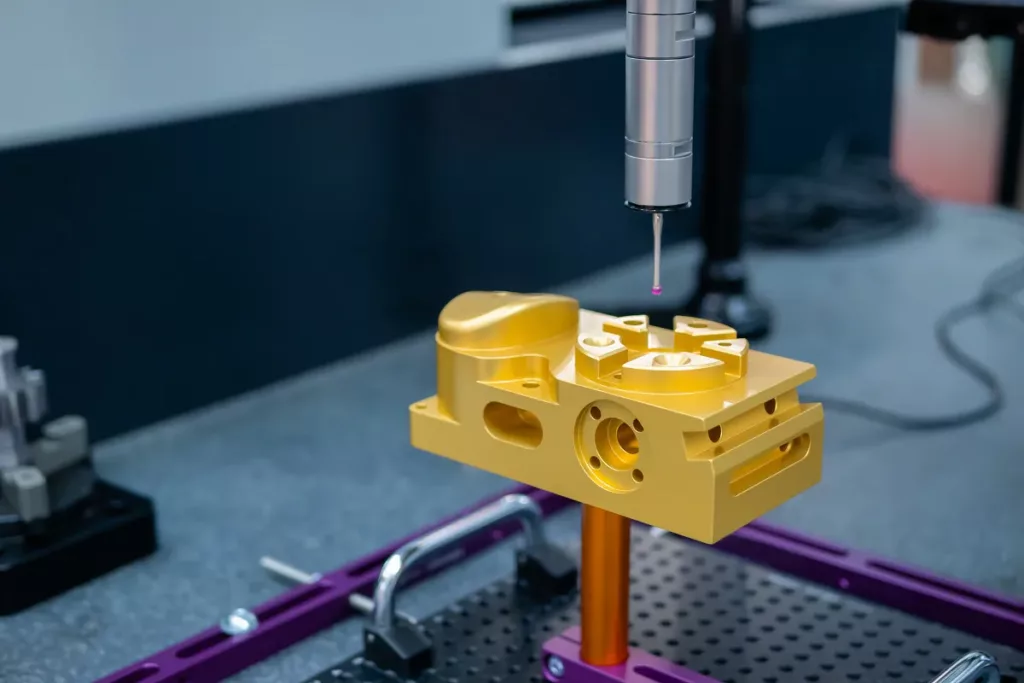

For the production of small accessories, punch presses are usually used for preliminary forming, followed by gong cutting or CNC (computer numerical control) processing. This processing method is particularly common in the fields of eyeglass accessories and automotive accessories, because they have extremely high requirements for the accuracy and size of parts. Through CNC machining, the shape, size and surface roughness of parts can be precisely controlled to meet the diverse needs of customers.

In the processing of large hardware such as containers, welding is usually performed after cutting and punching to ensure the stability and firmness of the structure. Subsequently, sandblasting is performed to remove the oxide layer and dirt on the surface and improve the adhesion and aesthetics of the paint. Then, oil spraying is performed to provide rust, corrosion and beautification effects. Finally, after assembling the necessary accessories and passing the quality inspection, it can be shipped.

For small hardware accessories, in addition to the above processing steps, a lot of grinding and surface treatment work is required. This includes removing burrs, scratches and other defects generated during the processing process, and performing surface treatment processes such as electroplating to improve the corrosion resistance and aesthetics of the parts.

In short, precision hardware processing is a complex process involving multiple links and multiple technologies. Through precise processing and fine surface treatment, high-precision and high-quality hardware parts that meet customer needs can be produced, providing strong support for the production and manufacturing of various industries.