Powder metallurgy, as an advanced material preparation and forming technology, has many significant advantages. Here is a detailed explanation of its top five advantages:

1. Eliminate or minimize machining:

The PM process can directly manufacture parts close to final size through processes such as powder pressing and sintering, greatly reducing the need for subsequent machining. This feature not only saves processing costs, but also shortens the production cycle and improves production efficiency. For some parts with complex shapes or that are difficult to achieve through traditional machining methods, PM technology provides an effective solution.

2.Eliminate or minimize scrap losses:

Compared with traditional melting and casting methods, the PM process has extremely low metal loss. In the powder metallurgy process, metal powder is directly pressed into a billet of the desired shape and sintered to achieve the desired physical and mechanical properties. The metal loss is usually only 1-5%. In traditional melting and casting methods, metal loss can be as high as 80%. Therefore, PM process has significant advantages in material utilization.

3.Maintaining tight dimensional tolerances:

The PM process is capable of producing high-precision and high-density parts. The one-time molding has small tolerance, high precision and density of over 90%. In addition, the accuracy and strength of parts can be further improved through processes such as shaping or re-pressing. This makes the PM process widely used in fields that require strict dimensional control, such as automobiles, aerospace, etc.

4.Allows multiple alloy systems:

The PM process has strong material adaptability and can process most refractory metals and their compounds, alloys and porous materials. This feature makes powder metallurgy technology an important means to prepare special materials, high-performance alloys and composite materials. By adjusting the composition and ratio of the powder, the alloy system that meets specific performance requirements can be flexibly designed.

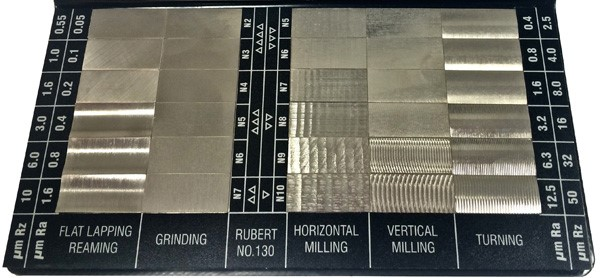

5.Produces a good surface finish:

Parts made by PM process have low surface roughness and can produce good surface finish. This is because the gaps between powder particles are effectively filled during the powder metallurgy process, and the slight deformation that occurs during sintering also helps to improve the surface quality. Good surface finish not only improves the aesthetics of the parts, but also enhances their wear and corrosion resistance

PM technology occupies an important position in the manufacturing industry due to its unique advantages. By eliminating or reducing machining, scrap loss, maintaining tight dimensional tolerances, allowing for a variety of alloy systems, and producing good surface finish, the PM process provides an efficient, energy-saving, and environmentally friendly solution for the manufacturing industry.

These advantages not only improve production efficiency and reduce production costs, but also improve product quality and performance. Metal powder metallurgy technology is widely used in many industries, including transportation, medical, aerospace, weapons and other industrial fields.