Continuing from the above, the remaining advantages of powder metallurgy are:

1.Provide materials that can be heat treated to improve strength or wear resistance:

Parts made by PM process can be further improved in strength and wear resistance through heat treatment processes (such as annealing, quenching, tempering, etc.). Heat treatment can change the microstructure of the material, thereby optimizing its mechanical properties. This feature is particularly important for parts that need to withstand high loads or wear environments. Shenzhen Yujiaxin Technology Co., Ltd., as a professional powder metallurgy processing company, can provide customers with customized heat treatment solutions to ensure that parts meet specific performance requirements

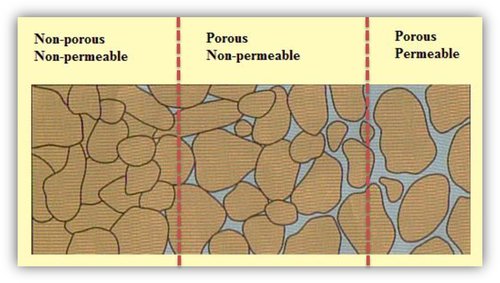

2.Provide controllable porosity to achieve self-lubrication or filtration:

PM process can control the porosity and pore size of the product, thereby producing porous materials with self-lubrication or filtration functions. This material has a wide range of applications in lubricating oil filtration, liquid separation, gas purification and other fields. By adjusting parameters such as powder particle size and pressing pressure, the porosity and pore structure can be precisely controlled to meet different application requirements.

3.Easy to manufacture complex or unique shapes that are difficult or impossible to achieve with other metal processing processes:

PM process has extremely high flexibility and can manufacture parts with complex or unique shapes that are difficult or impossible to achieve with other metal processing processes. This feature gives powder metallurgy technology unique advantages in the fields of automobiles, aerospace, medical devices, etc. Shenzhen Yujiaxin Technology Co., Ltd., with its rich experience and advanced technical equipment, can provide customers with a full range of services from design to production to achieve efficient manufacturing of complex-shaped parts.

4.Suitable for medium to high-volume component production requirements:

PM process is particularly suitable for medium to high-volume component production requirements based on its efficient manufacturing process. Through the automation and large-scale production of processes such as mold pressing and sintering, the production cost can be greatly reduced and the production efficiency can be improved. At the same time, the PM process can also ensure the consistency and stability of parts, ensuring the reliable quality of mass-produced parts.

5.Provide long-term performance reliability in critical applications:

Parts made by PM process have excellent mechanical properties and long-term performance reliability. Through strict process control and quality management, it can be ensured that the parts can maintain stable performance in harsh working environments. This makes the PM process have broad application prospects in key application fields such as automotive engines, aerospace and other fields.

6.Cost-effectiveness:

Considering factors such as material utilization, processing cost, and production cycle, the PM process has significant cost-effectiveness. By reducing scrap loss, reducing machining, and improving production efficiency, the production cost of parts can be greatly reduced. At the same time, the PM process can also provide high-quality parts to ensure that customers get the maximum value return.

We have found that it has significant advantages in providing materials that can be heat treated to improve strength or wear resistance, controllable porosity to achieve self-lubrication or filtration, manufacturing complex or unique shape parts, suitable for medium to high volume component production requirements, and providing long-term performance reliability. Shenzhen Yujiaxin Technology Co., Ltd. specializes in metal powder metallurgy processing, covering MIM metal powder injection molding, powder metallurgy pressing, precision casting, gear and gearbox manufacturing, etc. The company uses metal powder metallurgy technology to provide high-quality accessories and solutions for industries such as medical equipment and sports equipment.