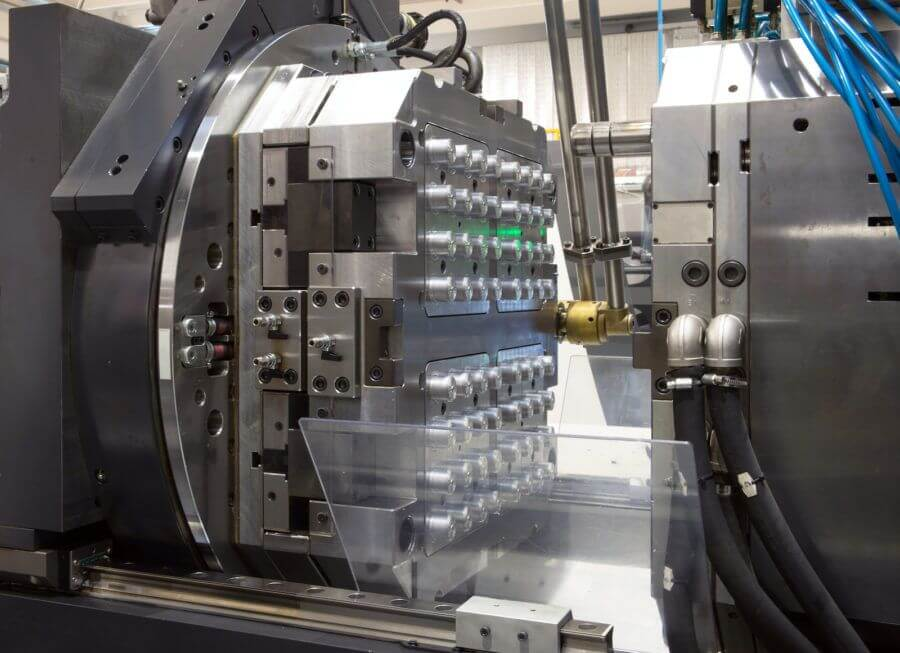

Injection molding is a major manufacturing process that involves injecting molten material into a mold cavity under high pressure to quickly produce different parts. Although injection molding is mainly associated with plastics, it can also be applied to metal products through the metal injection molding (MIM) process.

Injection molding is a process that produces parts by injecting molten material into a mold. The process is widely used to mass produce plastic parts, but it can also be used to produce certain metal parts.

Basic process:

Injection: Molten material is injected into the mold cavity under high pressure.

Cooling: The material cools and solidifies inside the mold to form its shape.

Ejection: After cooling, the part is ejected from the mold.

Metal Injection Molding (MIM) Process

Metal injection molding (MIM) is a manufacturing process that combines the versatility of plastic injection molding with the strength and integrity of metal parts. It involves mixing fine metal powder with a binder to create a feedstock, which is then injected into the mold cavity. After molding, the binder is removed and the part is sintered to achieve its final properties.

Traditional Metalworking vs. MIM:

1. Complexity: MIM can produce more complex geometries than traditional methods such as machining or casting.

2. Material Use: MIM generally produces less waste than subtractive processes such as machining.

3. Production Volume: MIM is more cost-effective for medium to large volume production.

4. Finishing: MIM parts generally require less post-processing than traditionally manufactured parts.

MIM is particularly useful for producing small, complex metal parts for industries such as automotive, medical devices, and consumer electronics. It bridges the gap between the shape complexity of plastic injection molding and the material properties of metals.

Common Products of Injection Molding

Injection molding can produce many plastic and metal products. Injection molding is able to produce complex shapes with high precision and speed, making it the preferred method for producing a variety of products.

Here are some common categories of plastic products that are often made using injection molding:

- Household goods

Containers, toys, and kitchen appliances

- Industrial parts

Gears, brackets, and housings

- Automotive parts

Instrument panels, trim, and under-the-hood components

Metal injection molding (MIM) expands the possibilities of metal part production and can be used to create complex, precision parts across a wide range of industries. The process combines the design freedom of plastic injection molding with the strength of metal.

Here are some common categories of metal products that are often made using injection molding:

- Automotive parts

Engine parts, transmission parts, steering system parts

- Electronics

Connectors, housings, internal components

- Medical devices

Surgical instruments, implants, diagnostic equipment parts

Industries that benefit from MIM include:

- Aerospace

- Automotive

- Consumer electronics

- Healthcare and medical devices

- Firearms

- Industrial machinery

- Jewelry

- Sporting goods

MIM’s ability to produce complex metal parts with high precision and consistency makes it invaluable in these fields. The process enables manufacturers to create parts that are difficult or impossible to produce using traditional metalworking methods, often at a lower cost and with less material waste.

Injection molding is at the forefront of modern manufacturing, demonstrating extraordinary versatility in both plastic and metal applications. The process has revolutionized production capabilities, making it possible to produce complex, precise and consistent parts at scale.

Shenzhen Yujiaxin Technology Co., Ltd., as a professional manufacturer in the field of Metal Injection Molding (MIM), is committed to providing customers with high-quality metal component solutions. The company utilizes advanced MIM technology, encompassing precise powder preparation, mixing, injection molding, as well as subsequent debinding and sintering processes, to produce metal products with complex shapes, precise dimensions, and excellent performance. During the MIM process, Yujiaxin Technology pays attention to every detail, from material selection to process control, ensuring the stability and reliability of product quality. Furthermore, the company boasts an experienced technical team capable of offering customized MIM processing solutions based on customers’ diverse needs. These solutions not only meet customers’ high requirements for metal components but also promote the application and development of MIM technology in more fields.