CAPABILITIES

We are The Metal Parts Manufacturing Experts.

Home > Capabilities > Metal injection molding

Capabilities

Contact Us

Email: info@szyujiaxin.com

Whatsapp:+8615986816992

skype:+8615986816992

wechat:yujiaxin-666

QQ:2269845694

Metal injection molding

Material Designation | Alloy Composition (wt%) | Condition | Density ρ (g/cm³) | UTS σb (Mpa) | YS σ0.2 (Mpa) | Elong ation σ(%) | Hardness |

Low Alloy Steel | |||||||

MIM4600 (MIM2200) | Ni 1.5~2.5% Mo 0.5% max Fe balance | Sinterd | 7.50 | 290 | 125 | 40 | 45~65HRB |

MIM4600 (modeifed) (MIM2700) | Ni 6.5~8.5% Mo 0.5%max Fe balance | Sinterd | 7.60 | 410 | 210 | 26 | 70~90HRB |

MIM4605 | Ni 1.5~2.5% Mo 0.2~0.5% C 0.4~0.6% Fe balance | Sinterd | 7.50 | 415 | 255 | 15 | 65-85HRB |

Heat Treated | 7.50 | 1655 | 1480 | 2 | 45~50HRC | ||

MIM4140 | Ni 0.75~1.25% Cr 0.75~1.25% Mo 0.75%max C 0.3~0.5% Fe balance | Sinterd | 7.50 | 820 | 620 | 10 | 70~100HRB |

Heat Treated | 7.50 | 1400 | 820 | 5 | 45~45HRC | ||

| Stainless Steel | |||||||

| MIM SS316L | C 0.03%max Ni 10~14% Mo 2~3% Cr 18~20% Fe balance | Sinterd | 7.75 | 500 | 250 | 4 | 65~85HRB |

| MIM SS304 | C 0.08% max Ni 8~10% Cr 18~20% Fe balance | Sinterd | 7.65 | 480 | 270 | 35 | 65~85HRB |

| MIM SS420 | C 0.2~0.4% Cr 12~14% Fe balance | Heat Treated | 7.40 | 1310 | 11500 | 6 | 40~45HRC |

| MIM 17-4PH | C 0.07%max Cr 15.5~17.5% Cu 3~5% Ni 3~5% Nb 0.15~0.45% Fe balance | Sinterd | 7.50 | 900 | 730 | 6 | 20~28HRC |

| Heat Treated | 7.50 | 1185 | 1090 | 5 | 32~42HRC | ||

| MIM SS310S | Sinterd | 7.70 | 520 | 205 | 40 | 80~100HRB | |

| Magnetic Materials | |||||||

| MIM Fe3Si | C0.05% Si 2.5~3.5% Fe balance | Sinterd | 7.60 | 530 | 390 | 24 | 75~85HRB |

| MIM Fe50Ni | C 0.05%max Ni 49~51% Fe balance | Sinterd | 7.70 | 455 | 160 | 30 | 50~65HRB |

| MIM Fe50Co | C 0.05%max Co 48~50% Fe balance | Sinterd | 7.70 | 205 | 140 | ~1.0 | 65~85HRB |

| MIM SS430 | C 0.05max Cr 16~18% Fe balance | Sinterd | 7.50 | 400 | 240 | 25 | 65~HRB |

| LOW Expansion/Glass Sealing Alloy | |||||||

Kovar (4J29) | Co 16.8~17.2% Ni 28.5~29.5% Fe balance | Sinterd | 8.00 | 510 | 345 | 25 | 65~80HRB |

Invar (4J36) | C 0.05%max Ni 35~37% Fe balance | Sinterd | 7.80 | 450 | 270 | 35 | 40~60HRB |

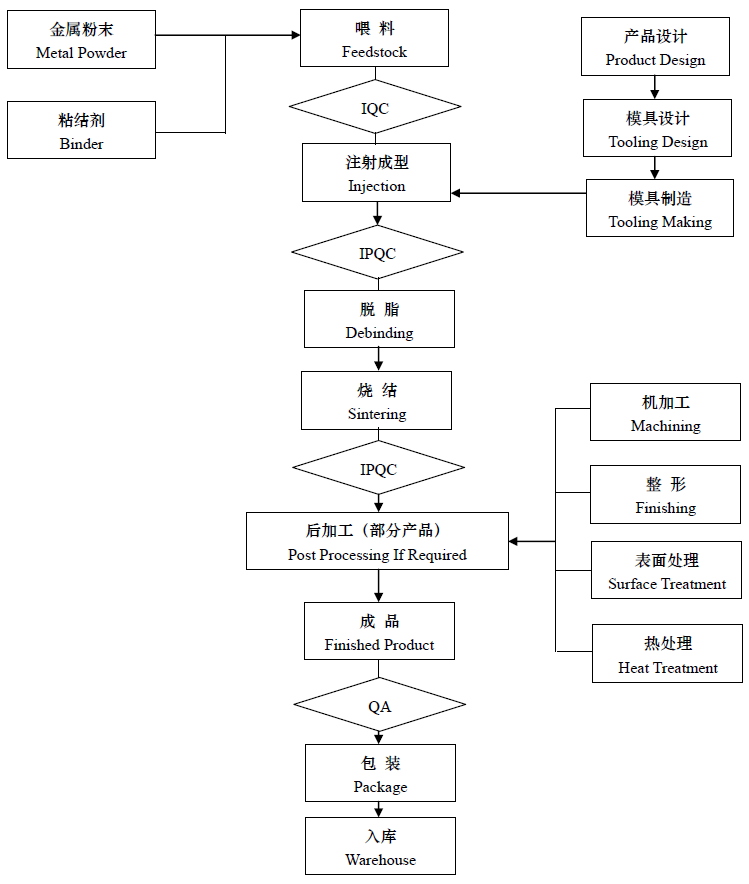

Process Flow Diagram for Metal Powder Injection Molding

Metal Injection Molding,or MIM,is a new Powder Metallurgy process that can produce sintered componects with high densety and complicated shapes without the need for machining. With its unique characteristics, MIM is capable of producing precise metal parts for a wide range of products, including automobiles, cellular phones,hand tools,dental instruments,pneumatic tools, power hand tools, surgical instruments,sporting goods, and laptop computers. The common materials used in MIM range from stainless steels and alloy steels to soft magnetic matericals.

Comparison between MIM and other processes

Comparison project | MIM | P/M | Die Casting | Investment Casting | Machining |

Part density | High | Low | High | Fair | High |

Part tensile strength | 0.5mm | 1mm | 0.8mm | 2mm | 0.5mm |

Part surface finish | Fine1 μm Ra | Coares | Medium | Medium 5 μm Ra | Fine |

Parts miniaturization capability | Good | Fair | Poor | Fair | Good |

Parts thin-walled capacity | Many | Average | Few | Average | Many |

Parts complexity | 95~100% | <95% | 99~100% | 99~100% | 99~100% |

Tolerance of part design | Average | High | Average | Average | High |

Mass production capacity | Good | Poor | Fair | Good | Good |

Adaptive material range | High | High | High | Fair | Low |

Supply capacity | Average | Low | Low | Average | High |