CAPABILITIES

We are The Metal Parts Manufacturing Experts.

Home > Capabilities > Powder Metallurgy

Capabilities

Menu

Contact Us

Email: info@szyujiaxin.com

Whatsapp:+8615986816992

skype:+8615986816992

wechat:yujiaxin-666

QQ:2269845694

Powder Metallurgy

Introduction

Material

Process Flow Diagram

Characteristics

Introduction

Introduction Of Powder Metallurgy

The process of manufacturing of shaped components or semi-finished products such as bar and sheet from metal powder is called as Powder metallurgy.

The technique of powder metallurgy combines unique technical features with cost effectiveness and generally used to produce sintered hard metals known as ‘carbides’ or ‘tungsten carbides’.

This technique deals with the production of metal and non metal powders and manufacture of components.

Powder metallurgy is generally used for iron based components.

The powders used as raw material can be elemental, pre-alloyed, or partially alloyed.

Elemental powders like iron and copper are more compressible and produce pressed compacts with good strength.

Pre-alloyed powders are harder but less compressible therefore require higher pressing loads to produce high density compacts.

Powder metallurgy technique has many advantage as well as limitation.

Two main techniques used to form and consolidate the powder are sintering and metal injection molding. Recent developments have made it possible to use rapid manufacturing techniques which use the metal powder for the products. Because with this technique the powder is melted and not sintered, better mechanical strength can be accomplished.

Principles of Powder Metallurgy Process

Powder metallurgy is the process of blending fine powdered materials, compacting the same into a desired shape or form inside a mould followed by heating of the compacted powder in a controlled atmosphere, referred to as sintering to facilitate the formation of bonding of the powder particles to form the final part. Thus, the powder metallurgy process generally consists of four basic steps.

(1) powder manufacture,

(2) blending of powders,

(3) compacting of powders in a mould or die

(4) sintering.

Compacting is generally performed at room temperature and at high pressure. Sintering is usually done at elevated temperature and at atmospheric pressure. Often, compacting and sintering are combined. Optional secondary processing often follows to obtain special properties or enhanced dimensional precision. Powder Metallurgy route is very suitable for parts that are required to be manufactured from a single or multiple materials (in powder form) with very high strength and melting temperature that pose challenge for the application of casting or deformation processes.

Material

Mechanical properties of structural Powder Metallurgy components

The mechanical properties available from the materials, commonly used for structural or engineering component applications, can be summarised as follows:

Ferrous Powder Metallurgy materials

Ferrous Powder Metallurgy materials, processed by the standard die press and sinter route, can deliver UTS levels up to around 900 N/mm² in the as-sintered condition or up to around 1200 N/mm² after heat treatment or sinter hardening.

These pressed and sintered materials can also deliver tensile yield stress levels up to around 480 N/mm2 as-sintered or around 1200 N/mm² after heat treatment or sinter hardening. Compressive yield stresses are slightly higher at up to around 510 N/mm² as sintered or up to around 1250 N/mm² heat treated.

These very significant levels of strength are, however, accompanied by quite low levels of tensile ductility (Elongation levels below 2% being quite typical). For this reason, PM products at conventional press/sinter density levels (up to 7.1-7.2 g/cm³ maximum) would not be used in applications likely to experience gross plasticity in service.

Powder forged steels

Powder forged steels can deliver high strength levels (UTS up to around 950 N/mm² as forged and 2050 N/mm² heat treated; tensile yield stress up to around 650 N/mm² as forged and 1760 N/mm² heat treated) with higher levels of ductility (5-18% Elongation).

Stainless steels

300 series PM stainless steels, in the Press/Sinter condition, can deliver UTS levels up to around 480 N/mm², tensile yield stress up to around 310 N/mm² and compressive yield strength up to around 320 N/mm², but with much higher ductility levels than their low alloy steel counterparts. (>10% Elongation).

400 series PM stainless steels can deliver similar properties to the 300 series materials in the as-sintered condition. Heat treatment of martensitic grades can increase strength levels to up to around 720 N/mm² UTS and tensile yield stress and 640 N/mm² compressive yield stress, but at the expense of a much reduced ductility (<1% Elongation).

Copper alloys

Press and sintered Cu alloys can deliver relatively modest strength levels (up to around 240 N/mm² UTS, 140 N/mm² tensile yield stress and 170 N/mm² compressive yield stress) but with much higher ductility than their ferrous counterparts (10-20% Elongation).

Aluminium alloys

Pressed and sintered Al alloys can deliver UTS of up to around 200 N/mm2 as sintered or up to around 320 N/mm² after heat treatment and tensile yield stress of up to around 170 N/mm² as sintered or up to around 320 N/mm² after heat treatment, but with quite low ductility levels (0.5-2% Elongation).

Fatigue strength

Both Press/Sinter Powder Metallurgy steels and Powder Forged steels are capable of providing significant levels of fatigue strength:

In the as-sintered condition, Press/Sinter PM steels can deliver fatigue endurance limits of up to around 320 N/mm² in the rotating bend loading mode and up to around 270 N/mm² in the axial loading mode (R = -1, Kt = 1).

Heat treatment can raise these values to up to around 540 N/mm² and 460 N/mm² respectively.

Powder forged steels can deliver fatigue endurance limits of up to around 420 N/mm² in the rotating bend loading mode and up to around 360 N/mm² in the axial loading mode (R = -1, Kt = 1).

Heat treatment can raise these values to up to around 635 N/mm2 and 560 N/mm² respectively.

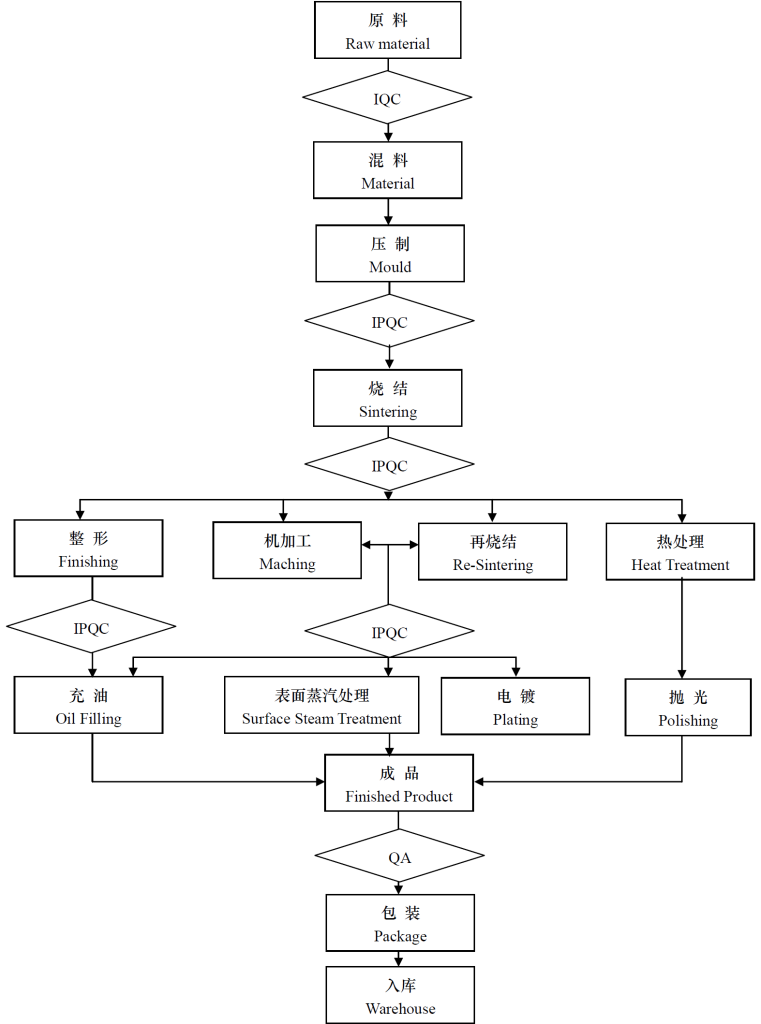

Process Flow Diagram

Process Flow Diagram for Powder Metallurgy

Characteristics

Advantages Of Powder Metallurgy

Metal in powder form is costlier than in solid form. Further, expensive dies and equipment needed to adapt this process implies that the process is justified by the unusual properties obtained in the products. Powder metallurgy offers the following specific advantages.

Parts can be produced from high melting point refractory metals with respectively less difficulty and at less cost.

Production rates are high even for complex parts. This is primarily because of the use of automated equipment in the process.

Near net shape components are produced. The dimensional tolerances on components are mostly such that no further machining is needed. Scrap is almost negligible.

Parts can be made from a great variety of compositions. It is therefore much easy to have parts of desired mechanical and physical properties like density, hardness toughness, stiffness, damping, and specific electrical or magnetic properties.

Parts can be produced with impregnation and infiltration of other materials to obtain special characteristics needed for specific applications.

Skilled machinists are not needed, so labour cost is low

Parts with controlled porosity can be produced

Bi-metallic products, sintered carbides and porous bearings can be produced only by this process.

Limitations Of Powder Metallurgy :

Powder metallurgy has the following limitations.

High cost of metal powders compared to the cost of raw material used for casting or forging a component. A few powders are even difficult to store without some deterioration.

High cost of tooling and equipment. This is particularly a limitation when production volumes are small.

Large or complex shaped parts are difficult to produce by PM process.

Parts have lower ductility and strength than those produced by forging.

Uniformly high – density products are difficult to produce.

Some powders (such as aluminum, magnesium, titanium and zirconium) in a finally divided state present fire hazard and risk of explosion.

Low melting point metal powders (such as of zinc, tin, cadmium) give thermal difficulties during sintering operation, as most oxides of these metals cannot be reduced at temperatures below the melting point.